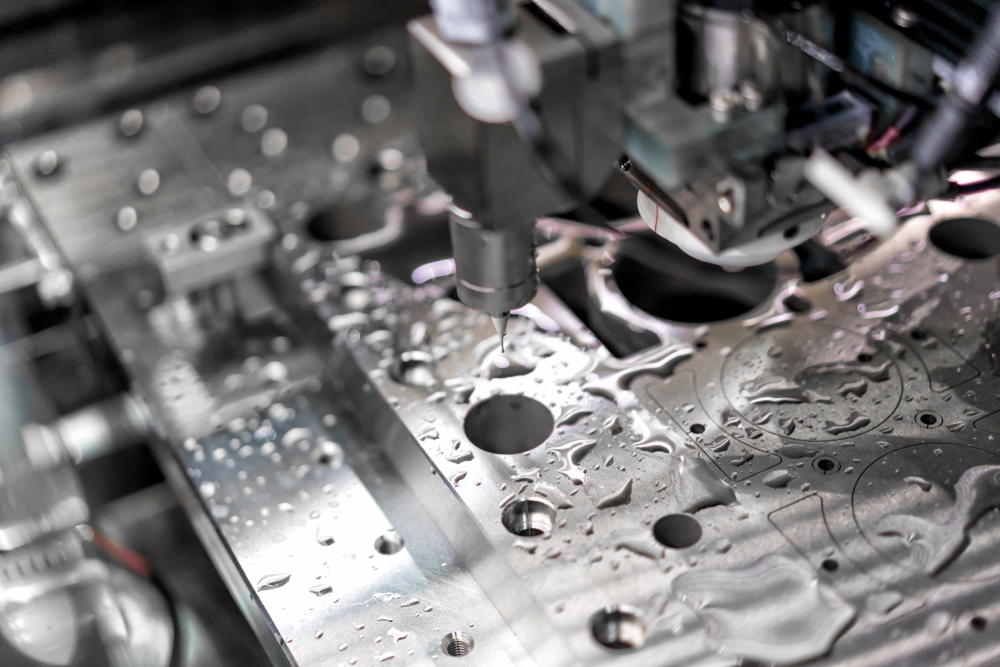

When customers are shopping around for machine shops to assist with their manufacturing project, they’ll often see phrases like “precision machining,” “high precision,” and “ultraprecision” without much clarification on what these terms mean or what makes a machine shop qualified to handle a high precision job.

In the manufacturing industry, “high precision machining” typically refers to machining parts with tolerances in the single-digit micron range, while ultraprecision involves tolerances in the sub-micron range. Machining parts with very tight tolerances are always a challenge; however, the complexity of a job is determined not only by required tolerances but also by the materials used and the number of features on the part.

High-precision machining is needed in all of the industries we serve – aerospace, dental, fluid motion, medical, sporting, and technology. However, we’ve been seeing a greater push toward higher precision, and ultraprecision work in the medical field as medical parts become smaller and more complex.

Any CNC machining shop has the ability to make high-precision parts. However, when looking to make these highly complex, high-precision parts, advanced machinery is required to do it efficiently, which is one reason Witeka acquired the Willemin earlier this year.

Additionally, while a qualified machinist can make a high-precision part, we’ve found that it’s important to incorporate precision into the entire manufacturing process, from our first consultation with a client to the final quality assurance check before the product goes out. High-precision machining is about so much more than creating a part that meets a spec. It’s about ensuring that the initial plan is designed to create a functional product in the most efficient and accurate way possible and integrating quality assurance checks throughout the process to ensure the entire final shipment meets the client’s needs.

Witeka has almost 40 years of experience in high-precision machining and would be happy to help you with your next project. Contact us to learn more about our services and capabilities.