#1

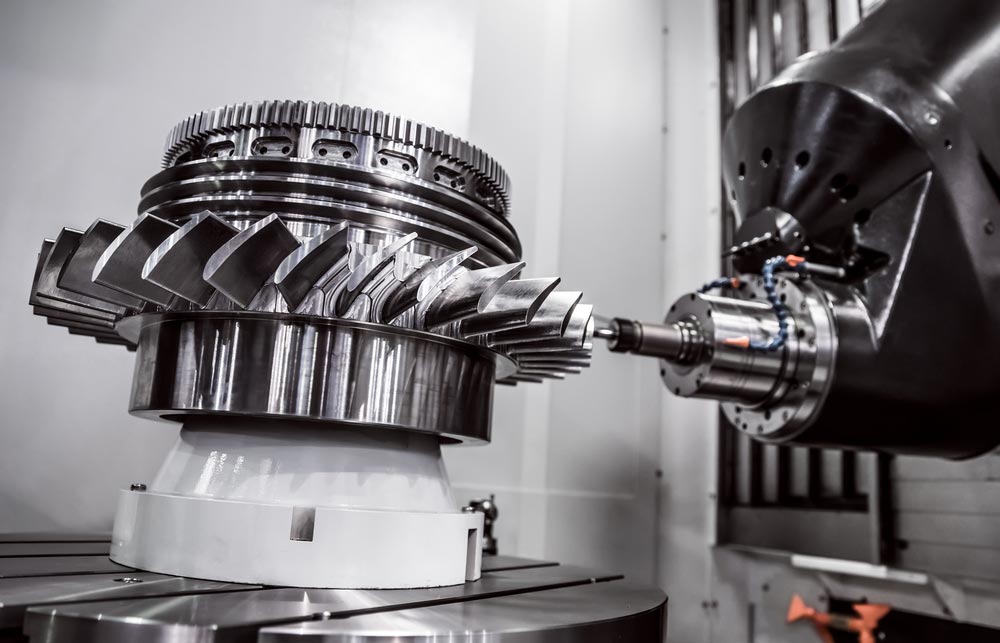

High precision machining is a cutting-edge process that involves the fabrication of intricate components with exceptionally accurate dimensions. This technique relies on advanced tools and modern machinery to deliver impeccable results. Precision is at the core of this approach, ensuring that every aspect of the machining process is executed with meticulous attention to detail. By utilizing specialized computer-aided design (CAD) software and applying various techniques such as grinding, milling, and turning, high precision machining achieves tight tolerances and exact specifications. The use of state-of-the-art equipment enables manufacturers to work with various materials, including metals, polymers, and composites, with exceptional accuracy. This methodology is integral in the production of components for industries such as aerospace, automotive, and medical devices where even the slightest deviation can have severe consequences. High precision machining is constantly evolving, constantly pushing the boundaries of what is achievable, and playing a vital role in creating complex parts that drive innovation in different sectors.

#2

High precision machining refers to the process of shaping and refining materials with meticulous accuracy and tight tolerances. It involves utilizing advanced equipment and cutting-edge techniques to create intricate parts and components for a wide range of industries. Precision machining plays a crucial role in various sectors, including aerospace, automotive, electronics, and medical devices, where the highest level of precision is essential. By employing highly trained professionals and state-of-the-art technology, manufacturers can achieve exceptional precision in their machined products. This level of precision ensures the proper functioning and interchangeability of parts, thus enhancing overall quality and performance. High precision machining requires close attention to detail, thorough planning, and the ability to work with extremely tight specifications. With the help of computer numerical control (CNC) machines, skilled operators can achieve even the most intricate designs with utmost accuracy and consistency, meeting the demanding standards of modern industries.

#3

High precision machining is a process that involves the manufacturing of intricate and accurate components with utmost accuracy and precision. This technique requires advanced machinery and highly skilled operators who can manipulate the tools with great precision. The goal of high precision machining is to produce parts with exacting specifications, often with tolerances measured in micrometers or even nanometers. This level of precision is crucial in industries such as aerospace, medical, and automotive, where even the tiniest deviation can lead to catastrophic consequences. High precision machining utilizes cutting-edge equipment, like computer numerical control (CNC) machines, which can control every movement with utmost accuracy and repeatability. With the aid of sophisticated software and state-of-the-art technology, manufacturers can achieve exceptional precision, resulting in flawless and reliable parts. By specializing in precision machining, companies can ensure the highest quality standards and meet the demanding requirements of various industries where precision is of paramount importance.